INDEPENDENT DEALER

Newark, NY | (315) 331-4642

Oil Analysis by Oil Analyzers, INC.

The Most Advanced Computerized Oil Analysis Laboratory in the U.S.Provides Used Oil Analysis for Engines, Transmissions, Gears, Hydraulics, Compressors & TurbinesCoolant Testing and Diesel Fuel Test Kits Available

Contact us today and we’ll e-mail you a FREE Oil Analyzers, INC. Fluid Analysis Program brochure!

Did you know oil tells a story and provides a working history of your equipment as well as the condition of your lubricant? With Oil Analyzers, INC. you can get a look “inside” your equipment and get the story without costly tear downs or unnecessary lubricant changes.

Oil Analyzers, INC. is the most advanced computerized oil analysis laboratory in the U.S. OAI boasts many years of experience testing synthetic and petroleum lubricants, providing quality used oil analysis no matter which type of lubricant you use.

Be proactive rather than reactive when it comes to protecting your equipment – buy an oil analysis kit and oil vacuum pump (below) today!

Diesel Engine

Gasoline Engine

Marine Engine

Natural Gas Engine

Dual Fuel Engine

LP Gas Engine

Manual Transmission

Automatic Transmission

Powershift Transmission

Hydrostatic Drive

Differential

Final Drive

Planetary

Hydraulic

CompressorTurbine

Bearings

Racing

Oil Analyzers' services include a full complement of oil, diesel fuel and coolant testing. They also offer many additional fluid analysis options, including industrial applications. Below are just some of the oil analysis programs that Oil Analyzers, INC. offers:

Automotive

The inexpensive, easy-to-take sample could possibly save you hundreds of dollars at a mechanic by finding mechanical issues before they cause problems. With Oil Analyzers, you can be confident each time you sit behind the wheel. Customers typically test their engine oil, but also can test their transmission fluid, gear oil, and coolant.

Diesel Fleet

Oil analysis is essential for any cost-effective over-the-road trucking program. Extending oil drains can reduce time spent performing vehicle maintenance. As any fleet operator understands, saving a few pennies a mile on maintenance costs can add up very quickly, saving thousands of dollars per year. Oil Analyzers makes it possible to determine effective and safe drain intervals. Operators typically test engine oils, transmission fluids, gear oils, coolants, and diesel fuel.

Agricultural

Agricultural applications can be hard on lubricants. Dirt, heat, and organic matter can all interfere with the intended function of a lubricant. Oil Analyzers has extensive experience analyzing a variety of lubricants in a variety of settings and can provide you the information you need to keep your agricultural equipment properly maintained.

Construction

Construction and heavy-duty machine applications work under tough conditions, placing added stress on lubricants. Keeping machinery operating is essential, as equipment downtime can result in huge losses and project delays. Oil Analyzers fluid analysis program provides detailed records of equipment condition, helping reduce downtime. Operators typically test engine oils, transmission fluids, gear oils, hydraulic fluids, coolants, and diesel fuel.

Industrial

The Oil Analyzers industrial program provides reliable and accurate maintenance data. Machinery that is properly maintained lasts longer with less downtime. In addition, practicing extended drain intervals can save significant money. Operators typically test engine oils, transmission fluids, gear oils, hydraulic fluids, coolants, and diesel fuel.

Marine

Marine lubricants are susceptible to water contamination, making it essential to follow the Oil Analyzers marine analysis program, which provides a comprehensive water-contamination test. Operators typically test engine oils, transmission fluids, gear oils, hydraulic fluids, coolants, and diesel fuel.

Note: Oil Analyzers, INC. does not test aircraft/aviation oils.

Oil Sample Kits

Oil Analyzers' oil sample kits come complete with instructions. When you mail your sample to their lab, the Oil Analyzers’ technical team will do the rest. They combine their years of analytical experience with state-of-the-art instrumentation to produce reliable, meaningful results from your samples. Oil Analyzers also has long-term experience with synthetic oil and their fully diagnostic reports are guaranteed accurate and easy to read.

Oil Analyzers' oil sample kits are available individually or per case of 50 or 100. Consumers have the option of purchasing the kits with return postage paid, or they can choose to pay when they return the kit for testing.

It’s easy to get started:Buy an oil analysis kit and oil vacuum pump (below), draw a sample, and submit the sample along with the completed form that comes with the test kit to Oil Analyzers, INC.

About Fluid Analysis

Fluid analysis is a preventive maintenance tool that provides diagnostic testing designed to evaluate lubricant condition, component wear and contamination in mobile and industrial applications. Routine fluid analysis can detect lubricant or equipment issues before major problems develop.

What Can Used Oil Analysis Tell Me?

Analyzing used oil samples has existed as long as lubricants have been around. Oil analysis can provide critical information for any equipment requiring lubricants – both gasoline and diesel engines, transmission, gears, bearings, and hydraulic systems. It’s useful for owners of passenger cars, over-the-road fleets, off-highway equipment, boats and high-performance vehicles. It’s also right for any industrial plant equipment. Today many construction equipment operators, transportation fleets and industrial plants rely on lube testing as an integral part of predictive/preventative maintenance.

Oil analysis is a useful tool for extending the service life of an oil. By analyzing used engine oil, a qualified lab can determine the degree of protection that an oil is delivering and make certain the oil has not been contaminated due to engine malfunction or defect.

Here are some issues oil analysis can answer for you:

Air filter failure

Viscosity out of spec, either high or low

Water or coolant contaminationFuel dilution of crankcase oil

Presence of fuel soot due to combustion inefficiencies

Accelerated oxidation

High nitration due to emission system problems

TAN (Total Acid Number) – indicating overheating (for non-crankcase lubricants)

TBN (Total Base Number) – indicating whether additives are still capable of providing adequate engine protection against corrosion (primarily for gasoline and diesel motor oils)

- Abnormal component wear in engines, gears, shafts, and bearings

What is Trend Analysis?

A single sampling analysis is useful in providing information when critical failure conditions exist. However, trend analysis – monitoring test data over an extended period of time – is a better tool for estimating the useful life or overall condition of your engine or equipment.

Trend analysis samples are taken and analyzed at regularly scheduled intervals. Comparing a component’s most recent samples to its historical data is instrumental in identifying trends that can pinpoint potential problems. Monitoring these trends enables early detection of internal abnormalities – tested values falling within acceptable limits may show a pattern of subtle variance, which could signal a developing problem. Combinations of wear metals can identify components within the machine that are wearing and help to identify minor problems before they become major failures. It is important to note that machines of the same type will accumulate contaminants and wear at different rates. Performing trend analysis on each machine is the most effective method of giving you an internal look at your equipment.

Using oil analysis to evaluate contaminants is a scientific approach to predictive maintenance. You’ll extend vehicle or machine life, head off major maintenance costs, and prevent catastrophic failure that can shut you down or leave you stranded. Oil analysis saves owners the cost of major repairs or engine replacement, and also allows owners to anticipate and schedule maintenance when downtime is most convenient.

Fluid Analysis Helps You Save Money

Because fluid analysis provides a comprehensive look at the condition of lubricants and internal component wear, tracking sample results over a period of time can help save money.

Prevent major problems. State-of-the-art fluid analysis identifies dirt, wear particles, fuel dilution, coolant and other contaminants that can cause catastrophic failure or significantly shorten equipment life.

Maximize oil drain intervals. Monitoring the condition of the oil allows you to optimize drain intervals so that you capitalize on the fluid’s full service life. Performing fewer oil changes minimizes maintenance costs and maximizes uptime

Extend equipment life. Monitoring system cleanliness and filtration efficiency can help you keep your equipment longer and significantly reduce replacement costs.

Maximize asset reliability. Testing and analysis ensure that equipment is up, running, and making money.

Increase resale value. Analysis results provide valuable sampling history documentation that justifies higher equipment resale values.

About Oil Analyzers, INC. Fluid Analysis

The Oil Analyzers Fluid Analysis Program protects valuable equipment by providing solutions for lubrication concerns through accurate and easy-to-understand fluid analysis, timely reporting and an unparalleled commitment to personal, friendly customer service. Oil Analyzers works with fully equipped laboratories staffed by highly trained analysts and offers a complete line of oil analysis services to help you get the most from your lubricants and extend the life of your equipment.

High-Quality Testing. Oil Analyzers Fluid Analysis is performed at independent ISO 17025 A2LA accredited testing laboratories. This is the highest level of quality attainable by a testing laboratory backed by the most stringent accrediting body in the industry. You can be confident that the results you receive are accurate, repeatable, and traceable to a standard.

Personalized Service. Oil Analyzers provides personalized customer service. Reports are easy to understand and recommendations are included so you know exactly what you should do to provide the best care for your equipment. In addition, Oil Analyzers' customer service representatives are available by phone and email to answer your questions.

Innovative Information Technology Solutions. Oil Analyzers' online reporting software, HORIZON®, delivers your results almost immediately after sample processing is complete. The software’s management reports take your fluid-analysis program to the next level by helping you manage your data and your program efficiently and effectively.

To enable faster turnaround times, Oil Analyzers, INC. has three state-of-the-art facilities across the U.S. With labs in Utah (Salt Lake City), Texas (Houston) and Indiana (Indianapolis), there is a facility available by ground within 48 hours from anywhere in the continental U.S. There is also an Oil Analyzers, INC. lab located in Edmonton, Canada. These labs are committed to completing reports quickly with 98% of reports available online within 24 hours.

Let’s Get Started With Your Oil Analysis!

1. Buy an Oil Analyzers Fluid Analysis Test Package

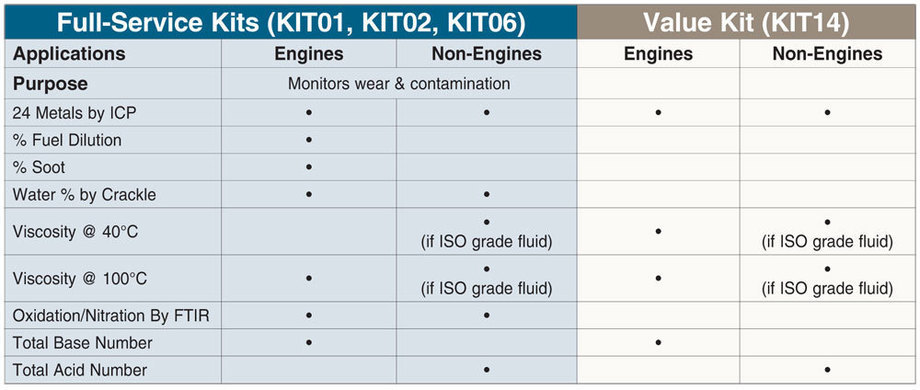

Oil Analyzers' fluid analysis provides diagnostic testing designed to evaluate lubricant condition, component wear and contamination in mobile and industrial applications with a test report provided by an independent laboratory for each sample submitted. Refer to the chart below to determine which combination of tests each component will receive.

Oil Analyzers Fluid Analysis Test Kits

Oil Analyzers Test Kit

Oil Analyzers offers several full-service test kits. These kits can be used for all drivetrain fluids except for coolant, which requires a different kit (see below). The physical kits are all the same – they only differ by the way the sample reaches the lab. KIT01 and KIT02 contain pre-paid shipping labels. KIT06 is less expensive, but the customer is responsible for shipping charges.

KIT401 and KIT402 are for Canada customers, as the samples go to the lab in Edmonton. Contact us to purchase.

Oil Analyzers Value Test Kit

The Value Test Kit is less expensive because fewer tests are performed on the sample, compared to the full-service test kits listed above. Use this kit when you only want to determine if your oil needs changing. If you want to set or extend oil drain intervals, or if you suspect abnormal contamination such as fuel dilution, a full-service kit is recommended.

Coolant Testing

Coolant testing requires a different kit than oil testing because entirely different tests are run on the sample. The lab will not test coolant samples that are sent in using an oil analysis test kit. It is important to completely identify the specific coolant being tested.

KIT403 is for Canada customers, as the samples go to the lab in Edmonton.Contact usto purchase.

Diesel Fuel Contamination Test

Tests fuel for water, sediments, and aerobic bacteria.

Requires 32 ounces of fuel.

Diesel Fuel Performance Test

Tests basic fuel quality, including metals, viscosity, calculated cetane index, distillation, and API gravity.

Requires 32 ounces of fuel.

Basic Winter Diesel Fuel Kit

Tests cold temperature of fuel including cloud point and pour point.

Requires 32 ounces of fuel.

Premium Winter Diesel Fuel Kit

Tests cold filter plug point, in addition to cloud point and pour point.

Requires 32 ounces of fuel.

Oil Sampling Pump

Oil Sampling Pump includes 10 feet of hose. The Oil Analysis Kits (sold separately above) contain bottle.

Product Code: G1206-EA

Replacement Hose – 25 Ft. for OAI Pump

Twenty-five foot hose for OAI Pump.

Product Code: G1571-EA

Postal Service Disclaimer

Equipment downtime while waiting for fluid analysis results is something everyone wants to keep to a minimum. Unfortunately, losing a test sample in the mail can extend this downtime even further and result in costly delays. That is why Oil Analyzers, INC. offers a UPS Prepaid Oil Analyzers, INC. Test Kit (KIT02-EA) that allows you to track your sample all the way to the lab so you will know exactly when it arrives.

If you choose the least expensive option, the Non-Postage Paid Oil Analyzers, INC. Test Kit (KIT06-EA), we suggest you use a trackable shipping service (such as FedEx, UPS, or USPS) that will enable you to track the progress of your sample and let you know if it has encountered delays. Oil Analyzers, INC. cannot be responsible for any samples lost in the mailing process.

2. Obtain an Oil Sample

Obtaining oil samples is relatively simple, regardless of the application. Sampling methods may vary according to the type of equipment from which the sample is taken. Mobile vehicles typically require a vacuum pump, while common industrial applications may give direct access through a sample valve or system reservoir. Some industrial equipment may require a vacuum pump.

Mobile Sampling Locations.Appropriate sampling locations for automobiles and light-duty, heavy-duty, and over-the-road trucks include the oil dipstick tube, the reservoir drain plug, or petcock valve, if one has been installed.

Industrial Sampling Locations.Common sampling locations include the oil reservoir, oil filter, sampling port, and filtration mount. If excess wear is detected in industrial applications, samples can be taken immediately before or after particular components, such as pumps or valves, to help isolate which component is producing excess wear elements.

To ensure accurate fluid analysis and reporting, appropriate procedures must be observed.

Oil Sampling Procedures

Oil analysis is most effective when samples are representative of typical operating conditions. Dirt, system debris, water, and light fuels tend to separate from the lubricants and coolants when system temperatures cool (dirt, water, and other debris tend to settle to the bottom of the reservoir, while light fuels tend to float). This separation will compromise your analysis. For optimum results, consider the following best practices:

Take samples while systems are operating under normal conditions or immediately after shutdown while they are still at operating temperatures

Take samples at regularly scheduled intervals

Take samples from the same sampling point each time

Do not sample a component directly after an oil change or after a large amount of makeup oil has been added

Collecting a clean and representative oil sample is critical to the oil analysis process. Put simply, an oil analysis is only as good as the sample taken.

Oil Sampling Methods

- Sampling with a Vacuum Pump. A vacuum pump is used to take samples from a dipstick or non-pressurized system. The pump is attached to the sample jar (included in the oil sample kit). Attach a clean tube (a 10-foot hose is included in the oil sample kit) to the top of the pump and tighten the lock ring. Place the free end of the tube into the dipstick tube or oil fill port, making sure not to allow contact between tubing and bottom of reservoir. Pump the plunger until oil flow is consistent, then pump only as needed to maintain consistent flow. Fill the sample bottle about 3/4 full or to its shoulder. Remove the sample bottle from the vacuum pump and tighten the lid securely.

The Oil Vacuum Pump will enable you to draw a sample quickly and easily. It comes with complete instructions and a 10-foot tube. Request Part #G1206-EAwhen ordering your oil analysis kit.

Sampling through a Sample Valve.Some industrial applications have a sampling port through which a sample can be obtained. This sampling method requires the equipment be in operation. Open the sampling valve and allow a small amount of oil to flush contaminants from the valve. Place the sampling bottle under the valve and obtain the sample. The sample bottle should be filled about 3/4 full or to its shoulder. Ensure the sampling valve is securely closed once the sampling process is complete.

Sampling from a System Reservoir.If collecting a sample through a sample valve is not possible, the equipment’s system reservoir can be used. The oil must be drained from the plug for a few moments before the sample is taken so contaminants that have settled around the drain are flushed out. Once the drain has been flushed, place the sample bottle in the oil stream and collect the sample, filling the bottle to about 3/4 full or to its shoulder. Using the reservoir drain plug is the least desirable method for obtaining an oil sample because the bottom of the reservoir contains elevated amounts of contaminants. It should only be used when the other options are unavailable.

Oil Sample Intervals

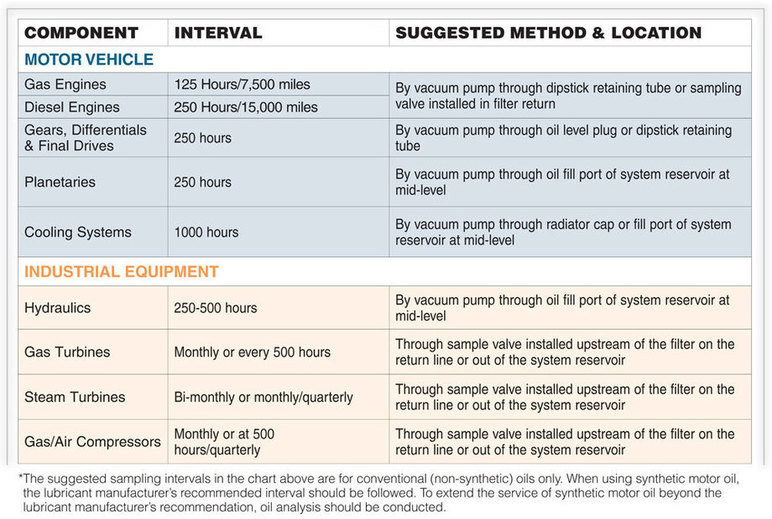

Although an equipment manufacturer’s recommendations provide a good starting point for developing preventative maintenance practices, sampling intervals can easily vary. A piece of equipment’s importance to production is a major consideration for determining sampling frequency, as are environmental factors such as hot, dirty operating conditions, short trips with heavy loads, and excessive idle times. See the chart below for suggested sampling intervals and methods.*

3. Submit Your Oil Sample

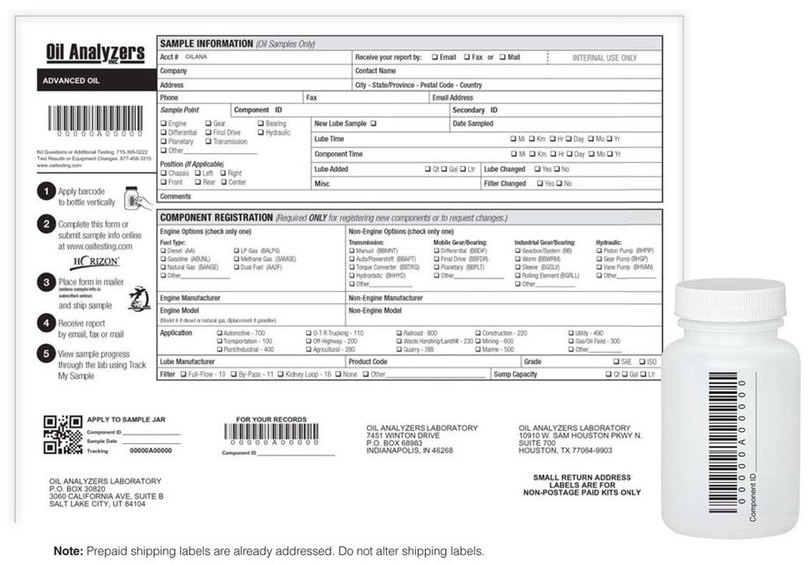

Accurately filling out a registration form, affixing a barcode label to the sample bottle, and sending the oil sample to the appropriate lab for analysis are the final steps in submitting an oil sample.

Component Registration Form

Accurate, thorough, and complete lube and equipment information not only allows for an in-depth analysis, but can eliminate confusion and difficulties that can occur when interpreting results.

A registration form (see blank form below) is included with every sample kit. Always complete the Sample Information section of the form. Fill out the Component Registration section of the form when sampling a component for the first time or to notify the laboratory of a change for a previously registered component or fluid. The Component Registration section of the form does not need to be completed if a previous sample has been analyzed for that specific Component ID and no information has changed. The laboratory will request additional information if the registration form is incomplete and there is no information on record from the last sample that was analyzed.

Barcode Label

The Component Registration Form includes a barcode that corresponds to the sample information you recorded on the form. Identical barcode labels are included on the bottom of the Component Registration Form.

- The barcode labeled “APPLY TO SAMPLE JAR” should be applied vertically to the oil sample bottle

- The barcode labeled “FOR YOUR RECORDS” should be maintained for your files

Send Your Oil Sample to the Appropriate Lab for Analysis

To enable faster turnaround times, Oil Analyzers, INC. has three state-of-the-art facilities across the U.S. With labs in Utah, Texas, and Indiana, there is a facility available by ground within 48 hours from anywhere in the continental U.S. Send your sample to the lab closest to you; their addresses can be found on the Component Registration Form. (There is also an Oil Analyzers, INC. lab located in Edmonton, Canada; their address can be found on the Canadian oil sample kit form.)

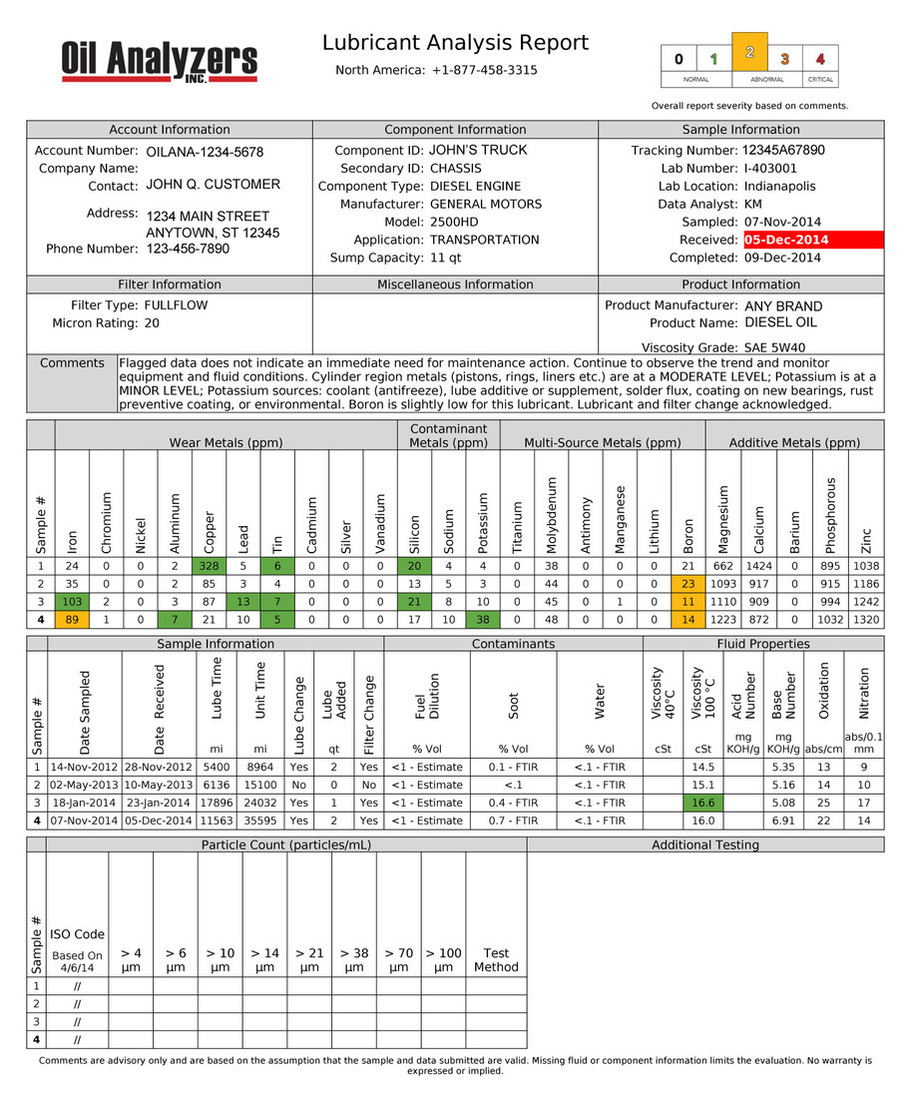

4. Read the Oil Analyzers Fluid Analysis Report

Oil Analyzers uses HORIZON® online reporting software for fast results, so your test results will be available almost immediately after processing your oil sample. Analysis reports are available via fax, email, or online. Fast access to oil analysis reports allows you to affect positive changes in your daily maintenance practices.

Details of a complete fluid analysis report (see sample report below) include:

- Customer and Equipment Information

- Comments and Recommendations

- Elemental Analysis

- Sample Information

- Contaminants

- Fluid Properties

This information is critical in determining the integrity of both the lubricant and the equipment

An Oil Analyzers, Inc. Lubricant Analysis Report includes oil analysis results and interpretation. For in-depth details and illustrations of what you can expect to find in your oil analysis report,contact ustoday for your FREE Oil Analyzers, INC. Fluid Analysis Program brochure!

Browse the full line of premium AMSOIL synthetic lubricant products at the AMSOIL, INC. Online Store.

You can also download or request by mail the latest factory direct AMSOIL Catalog. It's FREE!