INDEPENDENT DEALER

Newark, NY | (315) 331-4642

Engine Oil Treatment Additives: Are They Any Good?

The Potential Dangers of Using Engine Oil Treatments Erroneous Sales Claims Used by Aftermarket Engine Oil Additive Companies

Engine

oil treatments have been known to cause engine damage. The FTC has

charged Prolong, ZMax, Slick 50, Duralube and other engine oil additive

manufacturers with misleading consumers, as you will soon read below.

But, first, the bottom line up front: the best oil additive isn’t a

“treatment” at all and we’ll explain why you can confidently rethink

using motor oil additives.

The Best Oil Additive Isn’t a “Treatment” At All

AMSOIL

INC. works closely with major additive companies to select the

top-performing, and usually most expensive, motor oil additives. Then,

AMSOIL works with the additive company to maximize the amount of

additive used and to boost the additive package in selected performance

areas to achieve an optimum performing additive package in their motor

oils for the intended application. This is unlike many other oil

companies that, because oil additives are expensive, use the minimum

amount of the least expensive additives required to meet the minimum API

requirements.

AMSOIL also uses a combination of synthetic base stocks with known performance characteristics as replacements for petroleum base stocks to optimize performance in areas of lubricity, volatility, viscosity index, oxidation and nitration resistance, pour point, flash point, deposit control, soot handling, emissions and many other areas as well. AMSOIL also uses a high-quality V.I. (Viscosity Index) improver with outstanding viscosity and cleanliness properties. This replaces the inexpensive, low-quality V.I. improver used in standard API-licensed petroleum formulas.

AMSOIL

products and formulations are engineered and extensively tested for top

performance from the very beginning. Thanks, in part, to their superior

engine oil additive package, AMSOIL synthetic engine oils consistently

outperform conventional and other synthetic oils in virtually every

category of performance, including wear protection, extreme high- and

low-temperature performance, foam control, viscosity retention, rust and

corrosion protection, volatility and fuel economy. Drivers can have

confidence knowing that AMSOIL synthetic engine oils provide maximum

performance and protection. AMSOIL

saves you the expense of aftermarket engine oil additives and prevents

possible engine damage, as you will read about below.

Some Aftermarket Engine Oil Treatment Additives Contain Chlorine

Aftermarket engine oil additives are “treatments” advertised to enhance an oil’s properties. Manufacturers claim these treatments reduce friction, noise and wear; maintain higher lubricity and break down sludge and varnish, protecting the engine components. Many products advertise materials like Teflon, molybdenum or graphite; however, most fail to mention that they contain chlorine, which can be highly corrosive when mixed with water.

Chlorinated paraffins were once used as extreme pressure (EP) additives in lubricants, but the practice has been discontinued in most passenger vehicle lubricants due to the corrosive side effects. These chlorinated compounds are used due to their low cost and ability to provide EP properties, but they readily react with water and combustion by-products to form acidic materials that promote corrosion of engine components and bearings.

Lubes ‘N’ Greases published an article in August 1998 outlining the effects of chlorine on vehicle engine components. Author Maurice LePera explains the following:

Chlorinated additives are not used in modern, fully formulated automotive engine oils. The environment within an internal combustion engine consists of high operating temperatures, combustion and blowby gases, moisture, acid and oxidation precursors, wear debris, unburnt fuel, etc. The combination of these ingredients when combined with the catalytic effects of metallic surfaces and trace soluble metals such as copper will cause chlorine to hydrolyze – forming hydrochloric acid and other associated reaction products. Once generated, these acidic reaction products can cause serious internal engine corrosion problems, especially on ferrous and aluminum alloys. (1)

Furthermore, chlorinated paraffins tend to become more reactive as temperatures rise, making them exponentially more dangerous in hotter environments. “Chlorine-based additives can be film-forming even at ambient temperatures, but as the temperature rises they become aggressive and, with the release of HCI [hydrochloric acid], can cause significant corrosion.” (2)

Corrosion on the cam lobe or tappet face can also cause corrosive spalling, outlined in an engine failure case later in this bulletin. Because of the side effects of chlorine breakdown, many military and commercial specifications prohibit the use of chlorinated additives. For example, military specification MIL-PRF-17331J specifies, “[additives], if used, shall not contain chlorine.”(3) It’s worth noting that, “SAE J357 (Physical and Chemical Properties of Engine Oils) lists chlorine as a contaminant.”

In 2010, AMSOIL, Inc. initiated an independent lab study to determine if three engine oil additive products contained chlorinated ingredients and, if so, how much each contained. Three name brand products were tested and verified for chlorine content. Some of the products made reference to chlorine content and specifically stated, “contains no chlorine,” while others did not. However, based on the lab testing, each product contained high amounts of chlorine, one as high as 27%.

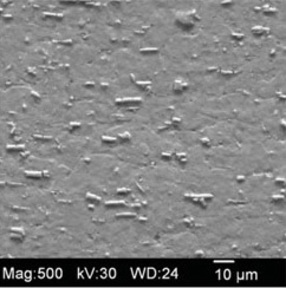

Corrosive attack on the roller to pin contact area of an injector cam follower pin in a Cummins OTR engine. Photo courtesy of Cummins, Inc.

An AMSOIL Technical Services investigation on a Cummins OTR ISX-485

engine failure revealed a high amount of chlorine in the engine oil. The

Cummins parts analysis determined the engine failure was the result of a

corrosive attack to the cam follower pins (see photo), causing valve

and injector camshaft lobe failures.

Galling to spalling damage on an intake valve cam follower roller in a Cummins OTR engine. Photo courtesy of Cummins, Inc.

Five injector lobes and four valve lobes were significantly spalled,

meaning the metal flaked off the surface of the lobes. Analysis of the

injector pin and valve pin showed corrosive attack in both the wear and

non-wear areas of the pins, while severe galling was observed on the

cams and cam follower pins. Galling is the transference of material when

moving parts are no longer fully separated and protected.

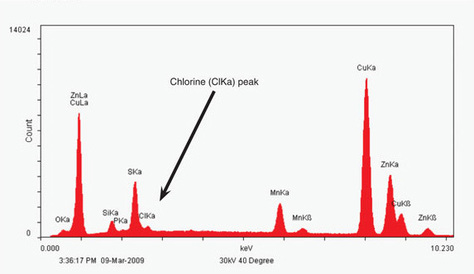

Furthermore, surface

analysis showed peaks of chlorine in the actual metal surface, which is

not normally present on a cam follower pin under normal operating

conditions (see graph).

Analysis showed chlorine in the actual metal surface from an engine oil treatment additive

The chemical data on

the lubricant and surface analysis of the failed engine parts revealed

the root cause of the failure was corrosive wear. Acidic components in

lubricants directly lead to corrosive wear. In this case, an abnormal

amount of chlorine was found in the engine oil. Chlorine, when combined

with hydrogen and water in the engine, can create hydrochloric acid.

This, in turn, can cause severe TBN depletion, which was the case with

this Cummins engine. It was determined that a chlorine-containing

additive was used when an oil sample from the engine tested at 11,000

ppm of chlorine. The result was an extreme corrosive environment which

was responsible for the upper end engine failure within 195,000 original

miles.

Bottom line, because HCI can lead to severe corrosion in the engine, chlorine additives are not considered a viable option for modern lubricants. (2)

Some Aftermarket Engine Oil Additives Contain EP Agents

Some aftermarket oil additives contain extreme pressure (EP) agents that can be harmful to engine components. Oxidation inhibitor, detergent and corrosion inhibitor performance is sacrificed when EP additives are added to fully formulated oil, leading to sludge formation and engine corrosion.

The FTC has charged multiple aftermarket additive manufacturers with misleading consumers into believing their products can offer extra protection when added to motor oils. The list of companies includes Prolong (4), Slick 50 (5), ZMax (6), Duralube (7), Shell Castrol (8) and Valvoline (9). In the Prolong case, the FTC specifically pointed out the use of “Friction Test Machine Demonstration” as a deceptive act (4).

Instead, the Standard Test Method for Wear Preventive Characteristics of Lubricating Fluid (Four-Ball Method), designation ASTM D-4172, is recognized by the ASTM and is used to evaluate the anti-wear performance of lubricants (2). Don’t be misled by non-ASTM certified testing demonstrations to sell oil additives that focus exclusively on EP performance in crankcase environments.

AMSOIL Saves You the Expense of Aftermarket Engine Oil Additives and Prevents Possible Engine Damage

AMSOIL synthetic motor oils are fully-formulated, high-quality engine oils blended with additives that are carefully balanced to be synergistic, performing well together. Tampering with this balance by adding other chemicals can adversely affect overall oil performance, sometimes dramatically. AMSOIL synthetic motor oils provide superior protection and performance, saving you the expense of aftermarket engine oil additives; use of aftermarket additives will detract from their performance and possibly lead to engine failure. Use of aftermarket engine oil additives not approved by AMSOIL INC. will void the AMSOIL Warranty.

To locate an AMSOIL retailer or oil change location near you, check out our sister website www.SuperOilUSA.com.

References:

- LePera, Maurice. (1998, August). Chlorine & Engine Oils: A Good Mix? Lubes ‘N’ Greases, pp. 16-20

- Rudnick, Leslie R. (2003). Lubricant Additives Chemistry and Applications. New York, New York: Marcel Dekker, Inc.

- MIL-PRF-17331J. (2003, September 09). Retrieved from http://www.wbdg.org/ccb/FEDMIL/prf17331j.pdf

- http://www.ftc.gov/opa/1999/09/prolong.htm

- http://www.ftc.gov/opa/1997/07/slick.htm

- http://www.ftc.gov/opa/2001/02/zmax1.htm

- http://www.ftc.gov/os/1999/05/duralubecmp.pdf

- http://www.ftc.gov/opa/1999/09/shellcastrol.htm

- http://www.ftc.gov/os/1997/10/ashland.htm